TNA @SUPRAtech

Supratech is part of the European Trans National Access Network, EUROLABS. If more than half the collaborators on an accepted proposal are from institutions outside France then the experiment can be eligible for Trans National Access financial support.

Supratech is part of the European Trans National Access Network, EUROLABS. If more than half the collaborators on an accepted proposal are from institutions outside France then the experiment can be eligible for Trans National Access financial support.

All access for research purposes at Supratech in the framework of EURO-LABS is evaluated by an international selection panel which is consulted on demand. Priority is following the rule “first come, first served” and also depends on technical adequacy with Supratech capabilities.

In the specific case of Supratech platform, which can provide surface treatment of Niobium materials and qualification tests of accelerator components as superconducting Niobium cavities or power coupler, EUROLABS is only supporting remote access. This allows selected users to use Supratech services at a reduced cost (consumables and running cost are covered up to a certain level).

To apply for EUROLABS support please contact first the Supratech scientific coordinator, David Longuevergne (david.longuevergne@ijclab.in2p3.fr), before applying on Eurolabs website. More information about the EUROLABS network can be found here: https://web.infn.it/EURO-LABS/

If you require further information, please don’t hesitate to contact us.

David Longuevergne and Richard Martret

Scientific and Technical Coordinators, Supratech facility, IJCLab

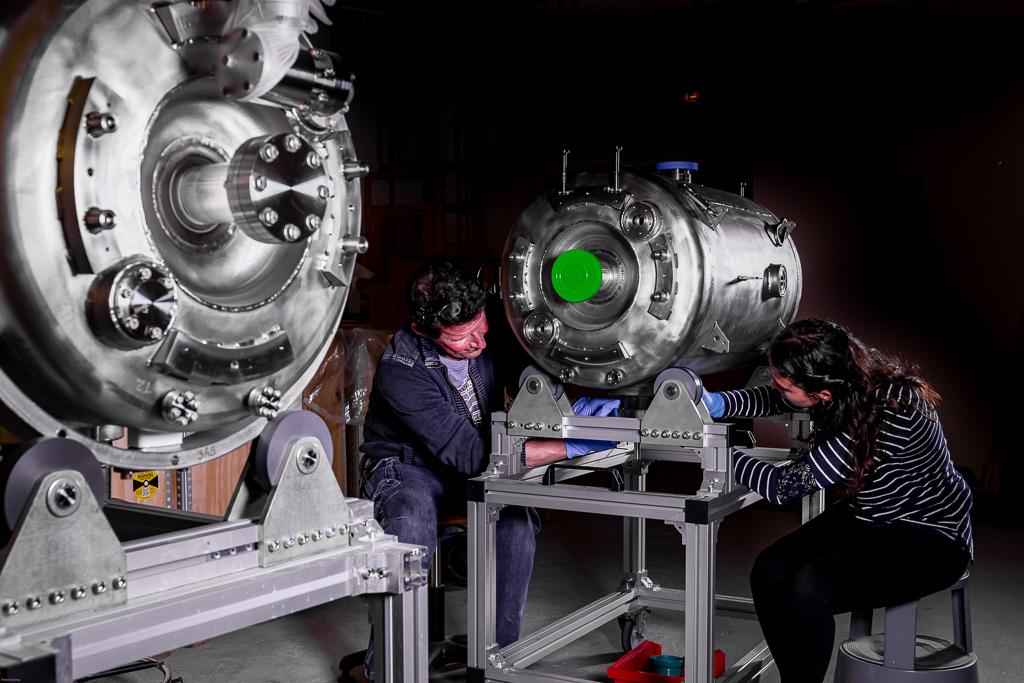

The SUPRATECH research platform is dedicated to R&D on superconducting accelerating cavities intended to constitute future powerful accelerators of high-energy particles. It provides all the equipment necessary to prepare, condition, assemble and test a superconductive cavity and its associated components, with in particular: an ISO4 clean room, a laboratory for surface treatment by chemical etching, an oven for thermal treatment under vacuum, an installation producing superfluid liquid helium, a calibration station for cryogenic thermometers, as well as various experimental zones equipped with RF power sources and several cryostats also allowing generic tests at cryogenic temperatures.

The platform consists of:

-

- an etching laboratory, where the cavity surfaces are treated in acidic baths, in order to eliminate all defects likely to generate electron spurious emissions.

- an ISO4 cleanroom, a high-technology equipment (covering 80 m2, 50m2 of which are class10) which is the essential link for the cleaning and assembly of superconducting cavities.

- an assembly hall, dedicated to the integration of the cryostats,

- two experimental halls, equipped with vertical and horizontal cryostats to test and RF validate the cavities.

To optimize the use of these infrastructures, the platform is equipped with :

-

- RF power sources operating at 88 MHz, 350 MHz and 700 MHz frequencies,

- a station including a helium liquefier and its associated recovery and compression system ; this very expensive gas, the release into the atmosphere of which would be anti ecological and which is here carefully recycled.

- a 400 kW cooling system (HF sources)